使用MPU9250获取实时运动数据

文件列表(压缩包大小 7.09M)

免费

概述

需要的元件

Arduino mega 2560

SparkFun IMU Breakout -MPU- 9250

Arduino IDE

原理及流程

运动处理是一个重要的概念。如果要与实时数据进行交互,则应该能够与运动参数进行交互,例如:线性加速度,角加速度,磁力。

MPU9250具有加速度计,陀螺仪和磁力计。我们可以从MPU9250获得的信息是:偏航,俯仰角和侧倾角。鉴于此,我将仅在本文中处理偏航。

处理来自MPU9250的数据

MPU的三个传感器均具有一个16位寄存器。它们临时存储来自传感器的数据,然后再通过I2C进行中继。

读取数据

我们一次接收8位数据,然后将它们连接在一起以再次形成16位。如下面的kriswiners代码片段所示:

fifo_count = ((uint16_t)data[0] << 8) | data[1];

packet_count = fifo_count/12;// How many sets of full gyro and accelerometer data for averaging

for (ii = 0; ii < packet_count; ii++) {

int16_t accel_temp[3] = {0, 0, 0}, gyro_temp[3] = {0, 0, 0};

readBytes(MPU9250_ADDRESS, FIFO_R_W, 12, &data[0]); // read data for averaging

accel_temp[0] = (int16_t) (((int16_t)data[0] << 8) | data[1] ) ; // Form signed 16-bit integer for each sample in FIFO

accel_temp[1] = (int16_t) (((int16_t)data[2] << 8) | data[3] ) ;

accel_temp[2] = (int16_t) (((int16_t)data[4] << 8) | data[5] ) ;

gyro_temp[0] = (int16_t) (((int16_t)data[6] << 8) | data[7] ) ;

gyro_temp[1] = (int16_t) (((int16_t)data[8] << 8) | data[9] ) ;

gyro_temp[2] = (int16_t) (((int16_t)data[10] << 8) | data[11]) ;

accel_bias[0] += (int32_t) accel_temp[0]; // Sum individual signed 16-bit biases to get accumulated signed 32-bit biases

accel_bias[1] += (int32_t) accel_temp[1];

accel_bias[2] += (int32_t) accel_temp[2];

gyro_bias[0] += (int32_t) gyro_temp[0];

gyro_bias[1] += (int32_t) gyro_temp[1];

gyro_bias[2] += (int32_t) gyro_temp[2];

}

校准原始数据

然后必须根据用户环境校准接收到的数据。需要对磁力计进行校准以补偿磁偏角。校正的确切值取决于位置。有两个必须校准的变量:偏航和磁偏角。

下面显示了特定磁偏角的偏航校准(印度钦奈的Potheri )。磁偏角数据可从不同站点获得:

yaw = atan2(2.0f * (q[1] * q[2] + q[0] * q[3]), q[0] * q[0] + q[1] * q[1] – q[2] * q[2] – q[3] * q[3]);

pitch = -asin(2.0f * (q[1] * q[3] – q[0] * q[2]));

roll = atan2(2.0f * (q[0] * q[1] + q[2] * q[3]), q[0] * q[0] – q[1] * q[1] – q[2] * q[2] + q[3] * q[3]);

pitch *= 180.0f / PI;

yaw *= 180.0f / PI;

yaw += 1.34; /* Declination at Potheri, Chennail ,India Model Used: IGRF12 Help

Latitude: 12.823640° N

Longitude: 80.043518° E

Date Declination

2016-04-09 1.34° W changing by 0.06° E per year (+ve for west )*/

请参见下面的代码片段[给定的代码片段,用于校正偏斜的数据来自另一个函数(magcalMPU9250(float * dest1, float * dest2)):

readMagData(magCount); // Read the x/y/z adc values

getMres();

// magbias[0] = +470.; // User environmental x-axis correction in milliGauss, should be automatically calculated

// magbias[1] = +120.; // User environmental x-axis correction in milliGauss

// magbias[2] = +125.; // User environmental x-axis correction in milliGauss

// Calculate the magnetometer values in milliGauss

// Include factory calibration per data sheet and user environmental corrections

mx = (float)magCount[0]*mRes*magCalibration[0] – magBias[0]; // get actual magnetometer value, this depends on scale being set

my = (float)magCount[1]*mRes*magCalibration[1] – magBias[1];

mz = (float)magCount[2]*mRes*magCalibration[2] – magBias[2];

}

自动校准磁力计

这是MPU代码中最简单和重要的部分之一。 当你在移动传感器时,该功能将magcalMPU9250(float * dest1, float * dest2)校准磁力计。它存储最大和最小读数并取平均值。

void magcalMPU9250(float * dest1, float * dest2) {

uint16_t ii = 0, sample_count = 0;

int32_t mag_bias[3] = {0, 0, 0}, mag_scale[3] = {0, 0, 0};

int16_t mag_max[3] = {0x8000, 0x8000, 0x8000}, mag_min[3] = {0x7FFF, 0x7FFF, 0x7FFF}, mag_temp[3] = {0, 0, 0};

Serial.println(“Mag Calibration: Wave device in a figure eight until done!”);

sample_count = 128;

for(ii = 0; ii < sample_count; ii++) {

readMagData(mag_temp); // Read the mag data

for (int jj = 0; jj < 3; jj++) {

if(mag_temp[jj] > mag_max[jj]) mag_max[jj] = mag_temp[jj];

if(mag_temp[jj] < mag_min[jj]) mag_min[jj] = mag_temp[jj];

}

delay(135); // at 8 Hz ODR, new mag data is available every 125 ms

}

// Get hard iron correction

mag_bias[0] = (mag_max[0] + mag_min[0])/2; // get average x mag bias in counts

mag_bias[1] = (mag_max[1] + mag_min[1])/2; // get average y mag bias in counts

mag_bias[2] = (mag_max[2] + mag_min[2])/2; // get average z mag bias in counts

dest1[0] = (float) mag_bias[0]*mRes*magCalibration[0]; // save mag biases in G for main program

dest1[1] = (float) mag_bias[1]*mRes*magCalibration[1];

dest1[2] = (float) mag_bias[2]*mRes*magCalibration[2];

// Get soft iron correction estimate

mag_scale[0] = (mag_max[0] – mag_min[0])/2; // get average x axis max chord length in counts

mag_scale[1] = (mag_max[1] – mag_min[1])/2; // get average y axis max chord length in counts

mag_scale[2] = (mag_max[2] – mag_min[2])/2; // get average z axis max chord length in counts

float avg_rad = mag_scale[0] + mag_scale[1] + mag_scale[2];

avg_rad /= 3.0;

dest2[0] = avg_rad/((float)mag_scale[0]);

dest2[1] = avg_rad/((float)mag_scale[1]);

dest2[2] = avg_rad/((float)mag_scale[2]);

Serial.println(“Mag Calibration done!”);

}

有关更多详细信息,请访问源:

https://github.com/kriswiner/MPU6050/wiki/Simple-and-Effective-Magnetometer-Calibration

永久校准特定位置

如果你不想每次都进行自动校准,则只需在计算了magbias []后记下平均值,并使用以下代码段即可:

readMagData(magCount); // Read the x/y/z adc values

getMres();

magbias[0] = +470.; // User environmental x-axis correction in milliGauss, should be automatically calculated

magbias[1] = +120.; // User environmental x-axis correction in milliGauss magbias[2] = +125.; // User environmental x-axis correction in milliGauss

// Calculate the magnetometer values in milliGauss

// Include factory calibration per data sheet and user environmental corrections

mx = (float)magCount[0]*mRes*magCalibration[0] – magBias[0]; // get actual magnetometer value, this depends on scale being set

my = (float)magCount[1]*mRes*magCalibration[1] – magBias[1];

mz = (float)magCount[2]*mRes*magCalibration[2] – magBias[2];

}

对于我的位置,值470、120、125是固定的,因此在执行此操作后,就不需要void magcalMPU9250(float * dest1,float * dest2)函数,因此你可以将其注释掉或将其删除。同样也不要忘记注释掉调用语句:

delay(1000);

// Get magnetometer calibration from AK8963 ROM

initAK8963(magCalibration); Serial.println(“AK8963 initialized for active data mode….”); // Initialize device for active mode read of magnetometer

getMres();

//magcalMPU9250(magBias,magScale); // commented call statement

if(SerialDebug) {

// Serial.println(“Calibration values: “);

Serial.print(“X-Axis sensitivity adjustment value “); Serial.println(magCalibration[0], 2);

Serial.print(“Y-Axis sensitivity adjustment value “); Serial.println(magCalibration[1], 2);

Serial.print(“Z-Axis sensitivity adjustment value “); Serial.println(magCalibration[2], 2);

}

筛选

因为原始数据包含很多噪声,所以我们在传感器的输出上使用某些滤波器将其转换为四元数(Madgwick / Mahony / Kalman):

void MadgwickQuaternionUpdate(float ax, float ay, float az, float gx, float gy, float gz, float mx, float my, float mz)

{

float q1 = q[0], q2 = q[1], q3 = q[2], q4 = q[3]; // short name local variable for readability

float norm;

float hx, hy, _2bx, _2bz;

float s1, s2, s3, s4;

float qDot1, qDot2, qDot3, qDot4;

// Auxiliary variables to avoid repeated arithmetic

float _2q1mx;

float _2q1my;

float _2q1mz;

float _2q2mx;

float _4bx;

float _4bz;

float _2q1 = 2.0f * q1;

float _2q2 = 2.0f * q2;

float _2q3 = 2.0f * q3;

float _2q4 = 2.0f * q4;

float _2q1q3 = 2.0f * q1 * q3;

float _2q3q4 = 2.0f * q3 * q4;

float q1q1 = q1 * q1;

float q1q2 = q1 * q2;

float q1q3 = q1 * q3;

float q1q4 = q1 * q4;

float q2q2 = q2 * q2;

float q2q3 = q2 * q3;

float q2q4 = q2 * q4;

float q3q3 = q3 * q3;

float q3q4 = q3 * q4;

float q4q4 = q4 * q4;

// Normalise accelerometer measurement

norm = sqrt(ax * ax + ay * ay + az * az);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f/norm;

ax *= norm;

ay *= norm;

az *= norm;

// Normalise magnetometer measurement

norm = sqrt(mx * mx + my * my + mz * mz);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f/norm;

mx *= norm;

my *= norm;

mz *= norm;

// Reference direction of Earth’s magnetic field

_2q1mx = 2.0f * q1 * mx;

_2q1my = 2.0f * q1 * my;

_2q1mz = 2.0f * q1 * mz;

_2q2mx = 2.0f * q2 * mx;

hx = mx * q1q1 – _2q1my * q4 + _2q1mz * q3 + mx * q2q2 + _2q2 * my * q3 + _2q2 * mz * q4 – mx * q3q3 – mx * q4q4;

hy = _2q1mx * q4 + my * q1q1 – _2q1mz * q2 + _2q2mx * q3 – my * q2q2 + my * q3q3 + _2q3 * mz * q4 – my * q4q4;

_2bx = sqrt(hx * hx + hy * hy);

_2bz = -_2q1mx * q3 + _2q1my * q2 + mz * q1q1 + _2q2mx * q4 – mz * q2q2 + _2q3 * my * q4 – mz * q3q3 + mz * q4q4;

_4bx = 2.0f * _2bx;

_4bz = 2.0f * _2bz;

// Gradient decent algorithm corrective step

s1 = -_2q3 * (2.0f * q2q4 – _2q1q3 – ax) + _2q2 * (2.0f * q1q2 + _2q3q4 – ay) – _2bz * q3 * (_2bx * (0.5f – q3q3 – q4q4) + _2bz * (q2q4 – q1q3) – mx) + (-_2bx * q4 + _2bz * q2) * (_2bx * (q2q3 – q1q4) + _2bz * (q1q2 + q3q4) – my) + _2bx * q3 * (_2bx * (q1q3 + q2q4) + _2bz * (0.5f – q2q2 – q3q3) – mz);

s2 = _2q4 * (2.0f * q2q4 – _2q1q3 – ax) + _2q1 * (2.0f * q1q2 + _2q3q4 – ay) – 4.0f * q2 * (1.0f – 2.0f * q2q2 – 2.0f * q3q3 – az) + _2bz * q4 * (_2bx * (0.5f – q3q3 – q4q4) + _2bz * (q2q4 – q1q3) – mx) + (_2bx * q3 + _2bz * q1) * (_2bx * (q2q3 – q1q4) + _2bz * (q1q2 + q3q4) – my) + (_2bx * q4 – _4bz * q2) * (_2bx * (q1q3 + q2q4) + _2bz * (0.5f – q2q2 – q3q3) – mz);

s3 = -_2q1 * (2.0f * q2q4 – _2q1q3 – ax) + _2q4 * (2.0f * q1q2 + _2q3q4 – ay) – 4.0f * q3 * (1.0f – 2.0f * q2q2 – 2.0f * q3q3 – az) + (-_4bx * q3 – _2bz * q1) * (_2bx * (0.5f – q3q3 – q4q4) + _2bz * (q2q4 – q1q3) – mx) + (_2bx * q2 + _2bz * q4) * (_2bx * (q2q3 – q1q4) + _2bz * (q1q2 + q3q4) – my) + (_2bx * q1 – _4bz * q3) * (_2bx * (q1q3 + q2q4) + _2bz * (0.5f – q2q2 – q3q3) – mz);

s4 = _2q2 * (2.0f * q2q4 – _2q1q3 – ax) + _2q3 * (2.0f * q1q2 + _2q3q4 – ay) + (-_4bx * q4 + _2bz * q2) * (_2bx * (0.5f – q3q3 – q4q4) + _2bz * (q2q4 – q1q3) – mx) + (-_2bx * q1 + _2bz * q3) * (_2bx * (q2q3 – q1q4) + _2bz * (q1q2 + q3q4) – my) + _2bx * q2 * (_2bx * (q1q3 + q2q4) + _2bz * (0.5f – q2q2 – q3q3) – mz);

norm = sqrt(s1 * s1 + s2 * s2 + s3 * s3 + s4 * s4); // normalise step magnitude

norm = 1.0f/norm;

s1 *= norm;

s2 *= norm;

s3 *= norm;

s4 *= norm;

// Compute rate of change of quaternion

qDot1 = 0.5f * (-q2 * gx – q3 * gy – q4 * gz) – beta * s1;

qDot2 = 0.5f * (q1 * gx + q3 * gz – q4 * gy) – beta * s2;

qDot3 = 0.5f * (q1 * gy – q2 * gz + q4 * gx) – beta * s3;

qDot4 = 0.5f * (q1 * gz + q2 * gy – q3 * gx) – beta * s4;

// Integrate to yield quaternion

q1 += qDot1 * deltat;

q2 += qDot2 * deltat;

q3 += qDot3 * deltat;

q4 += qDot4 * deltat;

norm = sqrt(q1 * q1 + q2 * q2 + q3 * q3 + q4 * q4); // normalise quaternion

norm = 1.0f/norm;

q[0] = q1 * norm;

q[1] = q2 * norm;

q[2] = q3 * norm;

q[3] = q4 * norm;

}

// Similar to Madgwick scheme but uses proportional and integral filtering on the error between estimated reference vectors and

// measured ones.

void MahonyQuaternionUpdate(float ax, float ay, float az, float gx, float gy, float gz, float mx, float my, float mz)

{

float q1 = q[0], q2 = q[1], q3 = q[2], q4 = q[3]; // short name local variable for readability

float norm;

float hx, hy, bx, bz;

float vx, vy, vz, wx, wy, wz;

float ex, ey, ez;

float pa, pb, pc;

// Auxiliary variables to avoid repeated arithmetic

float q1q1 = q1 * q1;

float q1q2 = q1 * q2;

float q1q3 = q1 * q3;

float q1q4 = q1 * q4;

float q2q2 = q2 * q2;

float q2q3 = q2 * q3;

float q2q4 = q2 * q4;

float q3q3 = q3 * q3;

float q3q4 = q3 * q4;

float q4q4 = q4 * q4;

// Normalise accelerometer measurement

norm = sqrt(ax * ax + ay * ay + az * az);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f / norm; // use reciprocal for division

ax *= norm;

ay *= norm;

az *= norm;

// Normalise magnetometer measurement

norm = sqrt(mx * mx + my * my + mz * mz);

if (norm == 0.0f) return; // handle NaN

norm = 1.0f / norm; // use reciprocal for division

mx *= norm;

my *= norm;

mz *= norm;

// Reference direction of Earth’s magnetic field

hx = 2.0f * mx * (0.5f – q3q3 – q4q4) + 2.0f * my * (q2q3 – q1q4) + 2.0f * mz * (q2q4 + q1q3);

hy = 2.0f * mx * (q2q3 + q1q4) + 2.0f * my * (0.5f – q2q2 – q4q4) + 2.0f * mz * (q3q4 – q1q2);

bx = sqrt((hx * hx) + (hy * hy));

bz = 2.0f * mx * (q2q4 – q1q3) + 2.0f * my * (q3q4 + q1q2) + 2.0f * mz * (0.5f – q2q2 – q3q3);

// Estimated direction of gravity and magnetic field

vx = 2.0f * (q2q4 – q1q3);

vy = 2.0f * (q1q2 + q3q4);

vz = q1q1 – q2q2 – q3q3 + q4q4;

wx = 2.0f * bx * (0.5f – q3q3 – q4q4) + 2.0f * bz * (q2q4 – q1q3);

wy = 2.0f * bx * (q2q3 – q1q4) + 2.0f * bz * (q1q2 + q3q4);

wz = 2.0f * bx * (q1q3 + q2q4) + 2.0f * bz * (0.5f – q2q2 – q3q3);

// Error is cross product between estimated direction and measured direction of gravity

ex = (ay * vz – az * vy) + (my * wz – mz * wy);

ey = (az * vx – ax * vz) + (mz * wx – mx * wz);

ez = (ax * vy – ay * vx) + (mx * wy – my * wx);

if (Ki > 0.0f)

{

eInt[0] += ex; // accumulate integral error

eInt[1] += ey;

eInt[2] += ez;

}

else

{

eInt[0] = 0.0f; // prevent integral wind up

eInt[1] = 0.0f;

eInt[2] = 0.0f;

}

// Apply feedback terms

gx = gx + Kp * ex + Ki * eInt[0];

gy = gy + Kp * ey + Ki * eInt[1];

gz = gz + Kp * ez + Ki * eInt[2];

// Integrate rate of change of quaternion

pa = q2;

pb = q3;

pc = q4;

q1 = q1 + (-q2 * gx – q3 * gy – q4 * gz) * (0.5f * deltat);

q2 = pa + (q1 * gx + pb * gz – pc * gy) * (0.5f * deltat);

q3 = pb + (q1 * gy – pa * gz + pc * gx) * (0.5f * deltat);

q4 = pc + (q1 * gz + pa * gy – pb * gx) * (0.5f * deltat);

// Normalise quaternion

norm = sqrt(q1 * q1 + q2 * q2 + q3 * q3 + q4 * q4);

norm = 1.0f / norm;

q[0] = q1 * norm;

q[1] = q2 * norm;

q[2] = q3 * norm;

q[3] = q4 * norm;

}

数据平均

由于数据变化非常快,我们采样了一段时间(50毫秒)并取平均值。

count = millis();

digitalWrite(myLed, !digitalRead(myLed)); // toggle led

}

}

else {

// Serial print and/or display at 0.5 s rate independent of data rates

delt_t = millis() – count;

if (delt_t > 50) { // update once per half-second independent of read rate

if(SerialDebug) {

提取现实世界的信息

最后,我们从四元数获得偏航,俯仰和滚动形式的读数。

yaw = atan2(2.0f * (q[1] * q[2] + q[0] * q[3]), q[0] * q[0] + q[1] * q[1] – q[2] * q[2] – q[3] * q[3]);

pitch = -asin(2.0f * (q[1] * q[3] – q[0] * q[2]));

roll = atan2(2.0f * (q[0] * q[1] + q[2] * q[3]), q[0] * q[0] – q[1] * q[1] – q[2] * q[2] + q[3] * q[3]);

pitch *= 180.0f / PI;

yaw *= 180.0f / PI;

yaw += 1.34; /* Declination at Potheri, Chennail ,India Model Used: IGRF12 Help

Latitude: 12.823640° N

Longitude: 80.043518° E

Date Declination

2016-04-09 1.34° W changing by 0.06° E per year (+ve for west )*/

roll *= 180.0f / PI;

Serial.print(“Yaw, Pitch, Roll: “);

Serial.print(yaw+180, 2);

Serial.print(“, “);

Serial.print(pitch, 2);

Serial.print(“, “);

Serial.println(roll, 2);

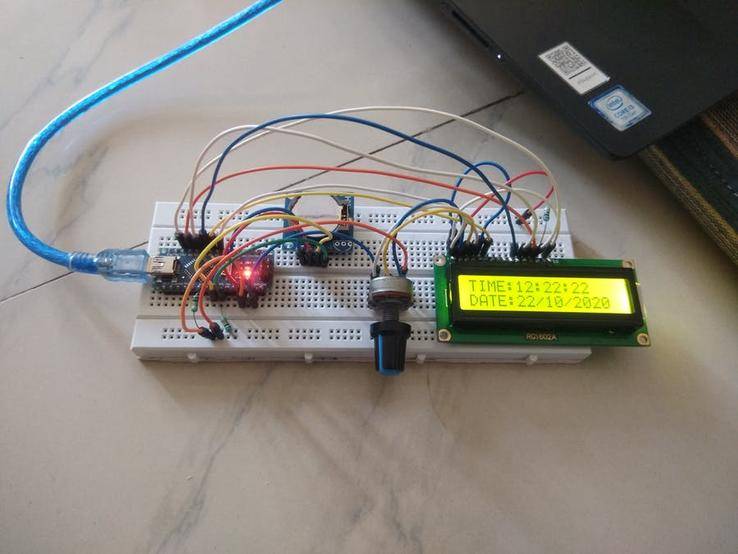

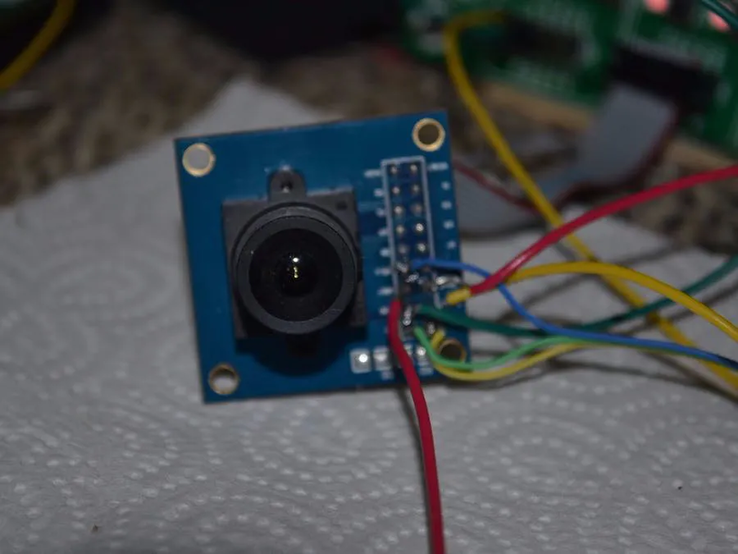

使用Arduino Mega 2560从MPU9250获取读数

我们有许多MPU9250的库。kriswiner提供了一种流行的方法:Kriswiner提供的MPU-9250 Arduino库

将库保存到Arduino文件夹后,即可开始使用。打开示例MPU9250BasicAHRS.ino.还准备好此设置:

MPU9250突破——— Arduino

- VIN ———————— 5V

- SDA ———————– SDA(引脚20)

- SCL ———————– SCL(引脚21)

- GND ———————- GND

这些导线不应太长,因为I2C连接不适用于长导线。

现在缩减MPU9250BasicAHRS代码。它具有LCD代码,但我们不需要它,因此请删除不必要的行。另外,我还添加了一部分自动校准代码。这是修改后的代码,没有不必要的代码,并且添加了自动校准:Github。

现在将代码上传到你的Arduino并进行上述连接。打开串行终端,并将波特率更改为115200。你应该看到以下输出:

MPU9250

9-DOF 16-bit

motion sensor

60 ug LSB

MPU9250 I AM 71 I should be 71

MPU9250 is online…

x-axis self test: acceleration trim within : 0.8% of factory value

y-axis self test: acceleration trim within : -1.9% of factory value

z-axis self test: acceleration trim within : 1.8% of factory value

x-axis self test: gyration trim within : -0.2% of factory value

y-axis self test: gyration trim within : 0.3% of factory value

z-axis self test: gyration trim within : 0.6% of factory value

MPU9250 bias

x y z

254913-660mg1.1-0.11.2o/s

MPU9250 initialized for active data mode….

AK8963 I AM 48 I should be 48

AK8963 initialized for active data mode….

Mag Calibration: Wave device in a figure eight until done!

如果看到以下内容:

MPU9250

9-DOF 16-bit

motion sensor

60 ug LSB

MPU9250 I AM FF I should be 71

Could not connect to MPU9250: 0xFF

这意味着肯定存在接线问题(或在最坏的情况下,MPu / arduino故障)请在尝试之前纠正此问题。

如果一切顺利,你会看到“ MPU处于联机状态”和“ Mag Calibration:图8中的波形设备,直到完成!” 然后一切正常,你应该将MPU调整为八字形,直到完成自动校准。一段时间后,你应该获得如下的偏航,俯仰和侧倾输出:

Mag Calibration: Wave device in a figure eight until done!

Mag Calibration done!

X-Axis sensitivity adjustment value 1.19

Y-Axis sensitivity adjustment value 1.19

Z-Axis sensitivity adjustment value 1.15

AK8963

ASAX

1.19

ASAY

1.19

ASAZ

1.15

Yaw, Pitch, Roll: 11.34, 28.62, 50.03

Yaw, Pitch, Roll: 20.47, 25.15, 52.88

Yaw, Pitch, Roll: 26.94, 19.02, 52.70

Yaw, Pitch, Roll: 28.22, 15.02, 50.15

Yaw, Pitch, Roll: 27.10, 13.94, 44.68

Yaw, Pitch, Roll: 23.11, 13.69, 37.51

Yaw, Pitch, Roll: 14.29, 13.22, 27.61

Yaw, Pitch, Roll: 357.03, 8.21, 16.72

Yaw, Pitch, Roll: 342.29, 0.69, 9.19

Yaw, Pitch, Roll: 328.42, -4.80, 3.16

Yaw, Pitch, Roll: 317.19, -10.51, -0.58

Yaw, Pitch, Roll: 311.88, -16.57, -3.64

Yaw, Pitch, Roll: 327.71, -23.45, -16.82

Yaw, Pitch, Roll: 325.74, -22.02, -23.51

Yaw, Pitch, Roll: 325.99, -28.17, -26.95

Yaw, Pitch, Roll: 324.57, -24.96, -23.21

Yaw, Pitch, Roll: 320.01, -26.42, -22.25

Yaw, Pitch, Roll: 322.50, -26.04, -26.62

Yaw, Pitch, Roll: 322.85, -23.43, -29.17

Yaw, Pitch, Roll: 323.46, -19.20, -31.48

这就意味着你有数据来

使用P-控制器对RTPT进行自动方位角(偏航)校准

我们首先通过执行以下操作将偏航从(-180到+180)转换为(0到360):

yaw = yaw + 180;

然后,我们只需使用简单的比例控制器在偏航中找到错误,然后将错误添加回偏航,然后使用新偏航进行伺服映射:

nyaw = 360 – yaw; //”yaw” comes from MPU which is “actual”

Azim = Azimuth – nyaw; /*”Azimuth” is the absolute azimuth which comes from calculations from RA and DEC which assumes our device is already aligned to North….by doing the subtraction we get the proportional error*/

Azim -= 90; //adding 90° because my titlt servo is mounted at an offset of 90°

while (Azim < 0)

Azim = 360.0 – abs(Azim); /*we use the error proportionally for our servo to auto adjust */

Azi = map(Azim, 0, 360, 5, 29);

Az = (int)Azi;

Elev = map(Elevation, -90, 90, 2, 178);

El = (int)Elev;

这样就完成了该项目。

所有代码在下载区均可找到。

最后

所有需要的文件在下载区均可找到。

理工酷提示:

如果遇到文件不能下载或其他产品问题,请添加管理员微信:ligongku001,并备注:产品反馈

评论(0)

0/250

理工酷

理工酷

资源下载

资源下载